- Contact Person : Ms. chen sunny

- Company Name : Shenzhen Zhuomao Technology Co., Ltd.

- Tel : 86-755-29929955

- Fax : 86-755-29929953

- Address : Guangdong,shenzhen,Building A, 4th Floor, Sanwei Section, Bao'an Road, Bao'an

- Country/Region : China

- Zip : 518126

BGA Rework Station ZM-R5880(ZM-R5850 upgrade)

Specification amd Technical parameters:

1 | Total Power | 6300W |

2 | Top heater | 800W |

3 | Bottom heater | 2nd heater 1200W,3rd IR heater 4200W |

4 | power | AC220V±10% 50/60Hz |

5 | Dimensions | 630mm(L)×720mm(W)×690mm(H) |

6 | Positioning | V-groove, PCB support can be adjusted in any direction with external universal fixture |

7 | Temperature control | K-type thermocouple (Closed Loop), independent heating, temperature precision within ±3 degree |

8 | PCB size | Max 380mm×450mm Min 10mm×20 mm |

9 | Electrical materials | Ming Wei Power+Touch screen( Taiwan)+Heating plate(Germany) |

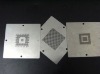

10 | BGA c | 2×2-70×70mm |

11 | Touch screen | 7.0", Resolution 640X480, Panel Visa touch screen |

12 | External temperature sensor | Three(optional) |

13 | Work Mode | Power drive |

|

Main features:

1. Adopt liner slide which makes X,Y,Z axis all can do precision adjustment or fast positioning, with high positioning accuracy and fast maneuverability.

2. High-definition touch screen (Taiwan) , PCL control, can save multiple groups profile, password protection and modify function, and can save multiple groups profile, equipped with instant temperature curve analysis function.You can analyze, set and calibrate the temperature parameters curve on the screen at any time.

3. There are 3 independent heating areas from top to bottom. The 1st and 2nd are hot-air heaters, the 3rd is IR preheating,Top and bottom temperature can control many groups and 6 sections of temperature parameters at the same time, the power consumption of the third IR heater can be adjusted.

4. Choose imported and high-precision K-type thermocouple, closed loop control and automatic temperature compensation system, combined with PLC module for the precision control of temperature, temperature precision controlled within ±3 °c. The external sensor can detect temperature precisely, analyze and calibrate the real temperature curve accurately.

5. Offer all kinds of hot-air nozzles, with 360°c rotation,With magnet, easy to install and change, customized is available, Bottom IR heater ensure an even heat for PCB board.

6. Use a V-groove equipped with a flexible fixture for PCB positioning to protect the PCB from deformation when heated or cooled, and it can rework any BGA package size.

7. Powerful cross-flow fan rapidly cool the PCB board to improve efficiency, Also built-in vacuum pump and external vacuum suction pen, pick up the chips rapidly.

8. CE certificate, with emergency stop and automatic power-off protection device when abnormal accident happens,with a double over-heating protection control.

BGA Rework Station ZM-R5880(ZM-R5850 upgrade)